High-throughput needleless electrodes

The NUENEX system is based on a special design of needleless electrodes. For water-borne polymers (i.e., collagen peptides, pullulan, PVA) the system utilizes bottom-filled needleless electrodes. Special design of electrodes simultaneously creates highly concentrated electric field in the spinning area and reduces dead volumes for maximal polymer efficacy. The jet density can reach 15 jets/cm2, overperforming standard needle-based devices (jet density maximally 1 jet/cm2). In addition, compared to standard needle-based devices, the needleless spinning enables optimal jet positioning based on self-organization of polymeric jets adaptively reacting to spinning conditions and reducing the need for compromising due to jet interference[1]. This results in a much higher production rate, easy adjustment of the electrospinning process and high product homogeneity.

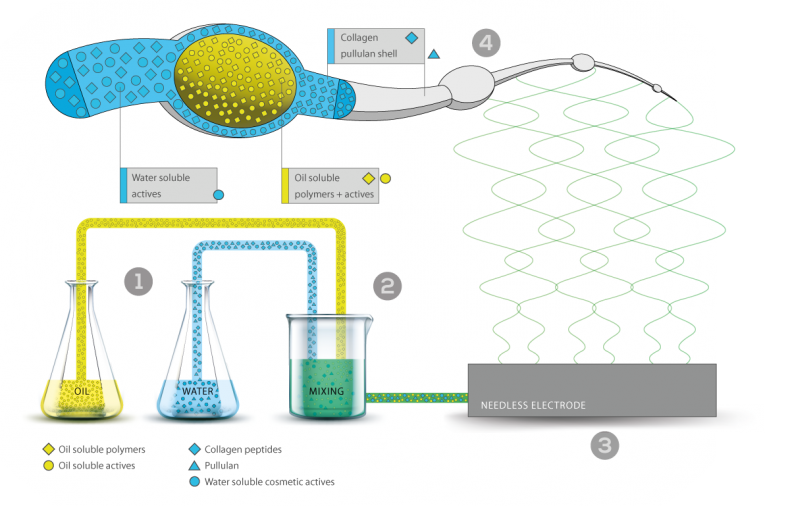

Needleless emulsion electrospinning

The NUENEX technology follows up on research work by Matej Buzgo (Head of R&D, RESPILON). The systems for high throughput production of core/shell fibers were described in his work for coaxial spinning[2], emulsion spinning[3] and emulsion centrifugal spinning[4]. RESPILON – a premium nanofiber provider since 2013 – made its long-standing know-how available to be combined with the knowledge described above, which gave rise to NUENEX – a novel nanoencapsulation technology. The combination of special polymer dosing elements, electrodes, and the overall system design resulted in the development of a technology enabling encapsulation of any active molecules into nanofibers and the finetuning of their release. The key advantage of emulsion spinning over blend spinning (used by most state-of-the-art systems) is the possibility to encapsulate active molecules in different phases (i.e., hydrophilic/hydrophobic) into a single fiber. This results in a higher formulation flexibility demonstrated in DrySerum membranes as cosmetic material enabling the encapsulation of water-based, oil-based, liposomal and nanoparticle-based active molecules into a single fiber. The active molecules are embedded inside the fibers, the system reduces phase separation and leads to better protection of the active molecules. What is more, the needleless system exceeds the production capacity of needle-based methods and enables economic production of materials with lower effort, higher energy efficacy and higher homogeneity.

Multi-electrode spinning systems for unprecedent versatility

The NUENEX system is designed as a modular spinning unit. Each electrospinning module can accommodate six high-throughput needleless electrodes in its 2-meter-long polymeric chamber reaching as much as 45,000 jets/m2. Each electrode has its own feeding system and can be used for the spinning of its own polymeric solution. Therefore, the system is ideal for multi-layered nanofiber membranes for enhanced functionality. NUENEX works both with special electrodes for water-based formulations and non-aqueous formulations. By selection of electrodes, spinning module configurations, and polymeric solutions you can design diverse multi-material nanofiber membranes and composites.

Efficacy and reliability first and foremost

The system is built with focus on efficacy of nanofiber production. The efficacy is encoded in the use of special highly productive electrodes, which enable a 2 GSM membrane (i.e., collagen peptides) to be reached with the speed of 45 mm/s per module. This makes NUENEX a workhorse for your nanofiber production. The system was designed to enable fast cleaning/changing of formulations. The complete change of electrospinning formulation takes approx. 15 minutes, which reduces the downtime of the device and reduces risk of cross-contamination. The efficacy and reliability require special high-quality components – NUENEX is based on premium materials and uses premium Japanese electronics and HV supplies. All important parameters are software monitored and regulated, which enables perfect control of the production process and reproducibility of the nanofiber production process.

The NUENEX technology brings innovation into electrospinning technology (needleless emulsion spinning technology) and as an engineering concept focused on maximally user-friendly and efficient system for active-molecule-enhanced nanofiber production.

[1] Lukas D. et al., Self-organization of jets in electrospinning from free liquid surface, 2008, DOI: 10.1063/1.2907967

[2] Vyslouzilova L. et al., Needleless coaxial electrospinning: A novel approach to mass production of coaxial nanofibers, 2017, DOI: 10.1016/j.ijpharm.2016.11.034

[3] Buzgo M. et al.: Needleless emulsion electrospinning for the regulated delivery of susceptible proteins, 2017, DOI: 10.1002/term.2474

[4] Buzgo M. et al: Emulsion centrifugal spinning for production of 3D drug releasing nanofibers with core/shell structure, 2017, DOI: 10.1039/C6RA26606A